Toyota 12r Engine Manual

Covers: Toyota 11Z, 12Z, 13Z, 14Z engines based on the following dates. 11Z, 12Z: December 1990.

13Z: September 1996. 14Z: July 1996 Pages: 228 Languages: English, Spanish Format: PDF file File size: 14mb Compatibility: Windows/Mac/Tablet Note: Instant digital download only – no printed copy or CD-ROM media. This repair manual contains maintenance, specifications and repair procedures for the Toyota 11Z, 12Z, 13Z, 14Z engine. View the repair manual on your computer or print off detailed specifications, service and maintenance instructions, including illustrations, as needed. Inside this manual you will find all the detailed information needed to correctly perform maintenance and repairs. Topics in the Toyota 11Z, 12Z, 13Z, 14Z Engine Repair Manual:. General Information.

Specifications. Torques. Engine Tune-Up (Inspection and Adjustment). Engine Overhaul.

Fuel System. Cooling System.

Lubrication System. Starting System. Charging System. Special Service Tools. Service Data Example Repair Manual content (actual manual may vary): How does this work?

It’s simple – after purchasing this manual through our secure checkout, a download link will be sent to the email address you specify at checkout. You have up to 30 days to retrieve and save the file. Once saved, the manual is yours for good. Have any questions or need more details? Related products.

During Break-In At 50 Miles (80 Kilometers): 1- Change engine oil and filter. 2- Inspect for fuel and oil leaks. 3- Inspect air cleaner element and service as required. 4- Check tightness of exterior fasteners, except head bolts. Engine Maintenance at 500 Miles (800 Kilometers): 1- Change engine oil and filter. 2- Inspect for fuel and oil leaks.

3- Inspect air cleaner element and service as required. 4- Check tightness of exterior fasteners, except head bolts. 5- Check operation of enrichment device and throttle controls. 6- Check engine idle speed. 7- Check tightness of engine mounts.

Regular Service Intervals Regular lubrication and maintenance will help keep your new S&S engine operating at peak performance. The following table presents the required service schedule for normal operating conditions. Failure to complete the required engine maintenance can result in engine damage and an increase in emissions.

Please refer to the motorcycle owner’s manual for any additional required chassis maintenance. Engine Service Intervals Item Interval Engine Oil & Filter Change at 50, 500, 2,500 miles (80, 800, 4,000 kilometers), every 2,500 miles (4,000 kilometers) thereafter1 Air Cleaner Element Inspect at 50 and 500 miles (80 and 800 kilometers), every 2,500 miles (4,000 kilometers) thereafter2 Tappet Oil Screen Inspect every 2,500 miles (4,000 kilometers). Replace every 5,000 miles (8,000 kilometers). Petcock, Lines, & Fittings, Vacuum Lines Inspect at 50 and 500 miles (80 and 800 kilometers), every 2,500 miles (4,000 kilometers) thereafter.

Fuel Tank Filter Screen & In-Line Fuel Filter (If used) Inspect every 5,000 miles (8,000 kilometers). Engine Idle Speed Adjust as required. Operation of Throttle & Enrichment Device ControlsInspect at 500 miles (800 kilometers) and every 2,500 miles (4,000 kilometers) thereafter. Spark Plugs Inspect every 5,000 miles (8,000 kilometers).

Replace every 10,000 miles (16,000 kilometers) or as needed. Ignition Timing Inspect every 5,000 miles (8,000 kilometers). Engine Mounts Inspect at 500 miles (800 kilometers) and every 5,000 miles (8,000 kilometers) thereafter. External Fasteners Except Engine Head Bolts Re-torque at 500 miles (800 kilometers) and every 5,000 miles (8,000 kilometers) thereafter.

1- S&S recommends that petroleum-based oil not specifically formulated for motorcycles should be changed every 1,000 miles (1,600 kilometers) after the break-in period. 2- Replace more frequently if required or if engine is operated in a dusty environment. Incoming search terms:. Fit the stand using the M8x18 screw to fasten it and the spring provided (photo 1 6). We suggest you to remove the stand during competitions as it could be dangerous and bruising. 18- Fit the gear lever lhoto 171. 19- Fill the fuel tank (See section 4.13).

20- Check the engine oil level (See section 4.3). INTRODUCTION Always ensure that the motorcycle has been efficiently serviced and check it over before riding it. Take your motorcycle to an authorised POIJNI MOTOR1 dealer for all maior servicing and repair. Because of the manufacturer’s policy OF continuous development, and because of constant innovations in technology, your motorcycle may differ in some details from that described in the illustrations and text in this manual. Original POLlNl MOTOR1 spare parts are always made from the same materials and in the same way as the parts originally fitted to your minicross motorcycle. Always insist on original POIJNI MOTOR1 spore parts. Their use ensures a longer life and improved efficiency for your motorcycle.

STARTING THE ENGINE FOR THE FIRST TIME Always check over your motorcycle thoroughly before starting the engine. To start the engine for the first time, as instructed below. 1 – Turn the fuel tap located under the fuel tank to #ON” position (photo 18) Run your new motorcycle in as instructed How to ensure that the engine and transmission bed in correctly and to ensure continuous reliability in Future. The first time yw ride your new motorcycle, ride for about two hours at low engine speeds to ensure that it runs in correctly. Also respect the following precautions. 2- Once the engine starts, leave it idle until it warms up to normal temperature. If you switch the engine off for a short time, wait for it to cool down completely before you re-start it.

– 3- During the running in period, always ride at constant 2- Before starting the engine put the gear in neutral position speeds. AVOID RAPID ACCELERATION.

(photo 19, gear N). 4- Even when riding at low engine speeds, avoid extended A WARNING! IF the gear position is not neutral the bike could move when started. 3- If the engine is cold, lift the choke lever on the carburettor (photo 20). Lower the starter lever again as won as the engine starts to warm up. 4- Leove the throttle closed. Pivot the kick-start lever out wards and push energetically downwards with your foot to start the engine.

5- Return the kick-start lever to its rest position. Leave the engine idle for a few minutes to warm it up. Check that the engine stop button stops the engine effectively before yw begin riding the motorcycle.

Difficult sections of road or Lck that could cause the engine to become very hot. 5- Once you have run in your motorcycle following all these instructions, take it to a Polini Motori dealer for its post- running-in service.

Apart from a change of spark plug and engine oil, this service also includes the disassembly Incoming search terms:. REMOVAL NOTE This Instruction Sheet covers several different Harley-Davidson models and years. Be sure to locate and follow the procedures that apply to the motorcycle receiving the new guard.

For Models without Lower Fairings 1. Proceed to For All Models section. For Model FLHTCUI (Ultra Classic Electra Glide) with Factory-Installed Lower Fairings 1. Remove the lower fairings following the instructions in the appropriate Service Manual. When the lower fairings have been removed, proceed to For All Models section.

For Models FLHR/I (Road King), FLHT (Electra Glide Standard) or FLHTC/I (Electra Glide Classic) with Harley-Davidson Genuine Motor Accessory Lower Fairings 1. See Figure 1.

Remove the two black screws (1) that attach the fairing cap (2) to the lower fairing (5). Remove the cap.

Set the parts aside for re-installation. Remove the screw (7), rubber washer (8) and locknut (10) and the clamp (9) that attaches the bottom of the lower fairing to the engine guard and set aside. Remove the two locknuts (3), U-bolt (6) and U-bolt retainer (4). Remove the lower fairing by sliding it out from behind the engine guard. Repeat Steps 1 through 4 for the opposite side. Proceed to For All Models section. For Model FLTR/I (Road Glide) with Harley-Davidson Genuine Motor Accessory Lower Fairings Disconnect negative (-) battery cable first.

If positive (+) cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion, which could result in death or serious injury. Disconnect the battery, negative (-) battery cable first, following the instructions in the appropriate Service Manual. Remove the seat following the instructions in the appropriate Service Manual.

Remove the cable strap holding the clutch cable to the engine guard. See Figure 2.

Remove the TORX screw (8), rubber washer (9) and locknut (11) and the clamp (10) that attaches the bottom of the lower fairing (4) to the engine guard and set aside INSTALLATION 1. Hold the engine guard in position, and loosely fasten the top of the guard with the new hex socket screw and flat washer from the kit. Install the bottom brackets to the motorcycle frame with the two new TORX screws and locknuts. Tighten all three screws to 15-20 ft-lbs (20.3-27.1 Nm). For Model FLHTCUI (Ultra Classic Electra Glide) with Factory-Installed Lower Fairings 1. Install the lower fairings following the instructions in the appropriate Service Manual. For Models FLHR/I (Road King), FLHT (Electra Glide Standard) or FLHTC/I (Electra Glide Classic) with Harley- Davidson Genuine Motor Accessory Lower Fairings 1.

Toyota 12r Engine Manual Download

Carefully place one lower fairing in position from behind the engine guard. See Figure 1. Install the lower fairing to the top of the new engine guard with the U-bolt (6) from the back, through the holes at the top of the fairing. Install the retainer (4) in position on the U-bolt and secure to the engine guard with the two locknuts (3). Do not tighten the locknuts at this time.

Attach the bottom of the fairing to the engine guard with the clamp (9) removed earlier. Install the clamp around the engine guard in the direction shown, with the tabs toward the rear of the vehicle and the flat side of the clamp against the lower fairing. Insert the screw (7) through the lower fairing, rubber washer (8) and clamp (9). Secure the assembly with the locknut (10). Tighten to 12 ft-lbs (16.3 Nm). Incoming search terms:.

REMOVAL Prepare for Service 1. Position motorcycle on a suitable lift. NOTE If vehicle is equipped with Harley-Davidson Smart Security System, see owner’s manual for instructions to disarm the system. To prevent accidental vehicle start-up, which could cause death or serious injury, disconnect negative (-) battery cable before proceeding. Disconnect battery cables, negative (-) battery cable first.

Remove seat according to the instructions in the service manual. Refer to service manual to remove left saddlebag and side cover. When servicing the fuel system, do not smoke or allow open flame or sparks in the vicinity. Gasoline is extremely flammable and highly explosive, which could result in death or serious injury.

Remove fuel tank according to the instructions in the service manual. Remove Engine Components 1.

Remove existing air cleaner assembly. Discard backplate but save remaining parts. Refer to AIR CLEANER REMOVAL in service manual. Remove existing exhaust system. Refer to EXHAUST SYSTEM REMOVAL in service manual.

Remove engine from chassis following the instructions in the service manual. Disassemble engine top end and bottom end. Refer to appropriate ENGINE sections in service manual. Remove existing clutch diaphragm spring. Refer to CLUTCH REMOVAL in service manual. The procedures in this instruction sheet should be performed by one experienced in precision measuring techniques.

Failure to meet tolerances called for in this instruction sheet can result in engine damage. (00511b) -J04793 1 2 is03517 1. O-ring counterbore 2. Spigot bore Figure 1.

Spigot Bore and O-Ring Counterbore Dimensions Table 1. Spigot Bore and O-Ring Counterbore Dimensions Depth Bore Description 1.625 +/- 0.010 in. (41.3 +/- 0.25 mm) 4.205 +/- 0.010 in. (107 +/- 0.25 mm) Spigot Bore 0.085 +/- 0.003 in. (2.16 +/- 0.08 mm) 4.415 +/- 0.002 in. (112 +/- 0.05 mm) O-Ring Counter- bore is03456 Figure 2. Cylinder Wall MACHINE CRANKCASE Crankcase Boring Preparation NOTE During final assembly of the engine, Harley-Davidson recommends replacing the OE cylinder studs with Screamin’ Eagle High Tensile Studs (16505-01).

Remove cylinder studs from the engine crankcase. Mask off all bearings and oil holes to prevent debris and contaminants from entering those areas.

Inspect and clean engine case mating surfaces. See Figure 6. Reassemble engine case with OE screws, except the top center screw between the cylinders, and tighten to specifications listed in service manual. NOTE To prevent damage to crankcase boring tool, it is important to replace the top center screw with a modified top center screw (1093).

This screw is included in the Crankcase Boring Tool Kit (94419-06) and can be purchased separately from a Harley- Davidson dealer. Install modified top center screw (1093) between the cylinders and tighten to 50-90 in-lbs (5.6-10.2 Nm). See Figure 1 and Table 1.

Machine crankcase cylinder spigot bore and O-ring counterbore to the dimensions shown. Modify Crankcase Incoming search terms:.

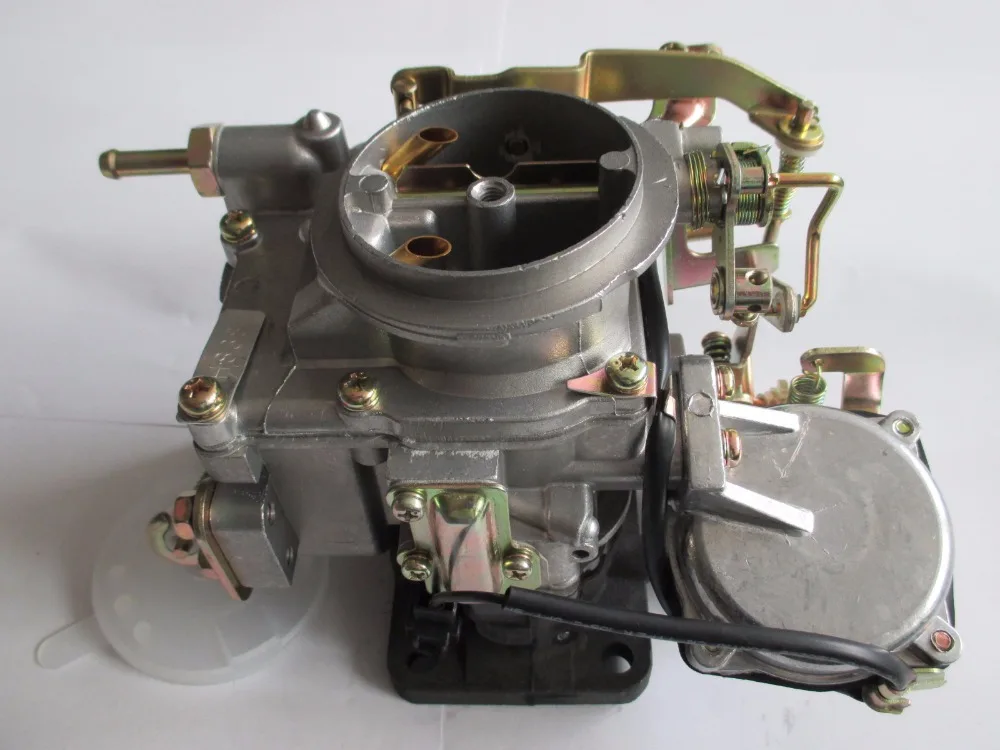

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E 2-2C main jet jet needle jet needle air control screw idle adjusting screw idle jet throttle valve Idling range A Operation with closed throttle valve. This range is influenced by the position of the air control screw 1 and the idle adjusting screw 2. Only make adjustments when the engine is hot. To this end, slightly increase the idling speed of the engine by means of the idle adjusting screw. Turning it clockwise produces a higher idling speed and turning the screw counterclockwise produces a lower idling speed.

Create a round and stable engine speed using the air control screw (basic position of the air control screw = open by 1.5 turns). Then adjust to the normal idling speed by means of the idle adjusting screw.

Opening up B Engine behavior when the throttle opens. The idle jet and the shape of the throttle valve influences this range. If, despite good idling-speed and part-throttle setting, the engine sputters and smokes when the throttle is fully opened and develops its full power not smoothly but suddenly at high engine speeds, the mixture to the carburetor will be too rich, the fuel level too high or the float needle is leaking. Part-throttle range C Operation with partly open throttle valve. This range is only influenced by the jet needle (shape and position). The optimum part-throttle setting is controlled by the idling setting in the lower range and by the main jet in the upper range. If the engine runs on a four-stroke cycle or with reduced power when it is accelerated with the throttle partly open, the jet needle must be lowered by one notch.

If then the engine pings, especially when accelerating under full power at maximum engine revs, the jet needle should be raised. If these faults should occur at the lower end of the part throttle range at a four-stroke running, make the idling range leaner; if the engine pings, adjust the idling range richer. Full throttle range D Operation with the throttle fully open (flat out). This range is influenced by the main jet and the jet needle. If the porcelain of the new spark plug is found to have a very bright or white coating or if the engine rings, after a short distance of riding flat out, a larger main jet is required. If the porcelain is dark brown or black with soot the main jet must be replaced by a smaller one. Mixture too rich: too much fuel in proportion to air mixture too lean: not enough fuel in proportion to air 1 2 OPERATING RANGES OF THE CARBURETOR 2-3C Carburetor adjustment Basic information on the original carburetor setting The original carburetor setting was adapted for an altitude of approx.

500 meters (1600 ft.) above sea level, and the ambient temperature of approx. 20°C (68°F), mainly for off-road use and central European premium-grade fuel (ROZ 95 MOZ). Mixing ratio 2-stroke motor oil: super fuel 1:40 – 1:60. Basic information on a change of the carburetor setting Always start out from the original carburetor setting. Essential requirements are a clean air filter system, air-tight exhaust system and an intact carburetor.

Experience has shown that adjusting the main jet, the idling jet and the jet needle is sufficient and that changes of other parts of the carburetor will not greatly affect engine performance. RULE OF THUMB: Incoming search terms:.